Dot Pin Marking Machine

Dot Pin Marking Machine

Dot peen marking machines are an excellent choice for product identification due to their durability and versatility. They use a high-frequency vibrating metal punch, which is electronically controlled, to create alphanumeric characters or drawings through a series of micro-points on various materials.

- Fast and accurate part marking, from light engraving to deep marking

- Durable, reliable machines designed for the harshest industrial environments

- Effortless programming with an extremely friendly operator interface

- Advanced integration capabilities for factory automation networking

- Pannier’s application and integration experts provide world-class support

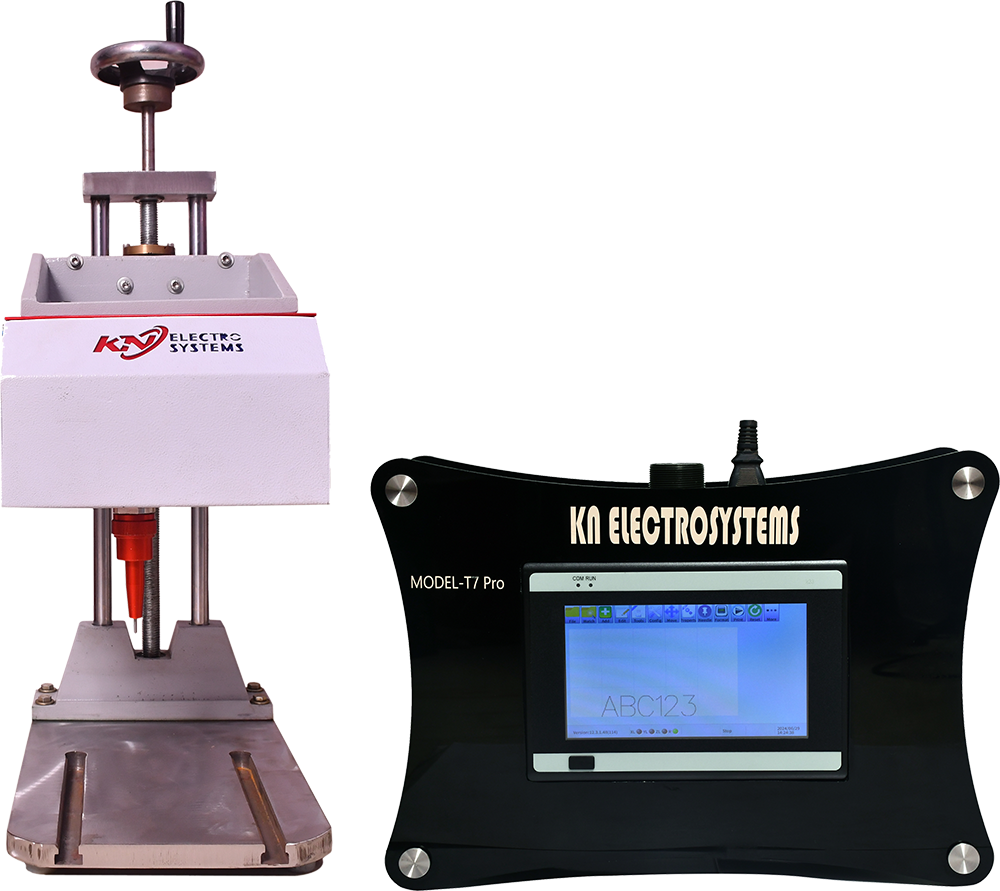

T7 Pro Controller

Streamlined Program and Settings Management

The T7 PRO is compatible with any KN marking head system, as well as dot peen systems from other manufacturers, making it easier to create and manage marking files across different systems within your facility. Additionally, the T7 PRO software can be installed on a PC, enabling effortless management of marking patterns and settings, with the option to upload and download files via the USB port.

Our commitment to excellence and innovation positions Wandtech India at the forefront of technological advancements. We are dedicated to meeting the growing demand for energy-efficient and environmentally friendly solutions. Through continuous research and development, we strive to provide cutting-edge technologies that not only enhance operational efficiency but also contribute to a sustainable future.

Fields can be added to a marking job effortlessly, one at a time. Simply click the Add button, select the desired field type (such as text, graphic, 2D code, etc.), and input the information to be marked in the field. You can also adjust the field’s height, width, spacing, and position as needed.

Additionally, fields can utilize variable data, which can be automatically updated. This data can be entered by the operator, pulled from a lookup table, scanned via a barcode scanner, or retrieved from a host computer or other connected device

Mannual Data Entry

- To modify a field, simply select it and enter the data to be marked.

- You can use the T7 PRO 10-inch touchscreen or a connected keyboard and mouse for this task.

Data Protection

- Utilize variable fields that allow operators to make modifications, while keeping other fields locked for consistency.

- Implement a query table to store data, enabling the operator to choose from predefined options.

CSV Files*

- Import a CSV file, choose a starting value, and the field will automatically increment to the next value after each marking.

- Use Pannier’s Simple Spreadsheet App to transfer data directly from a spreadsheet on a connected PC.

Scan Barcodes

- Scan barcodes on job paperwork to automate the data entry process.

- For more complex data retrieval and verification requirements, Pannier can also develop custom software solutions.

DISCRETE I/O

The T7 PRO model supports both NPN and PNP signals, with potential-free I/O connections for enhanced system safety. It also allows remote control of operations, such as selecting files, putting the system online, starting marking, and stopping marking.

Extended protocol

- Connect to a PLC or host computer via Ethernet or serial.

- The T7 PRO's Extended Protocol enables two-way communication with built-in error checking.

Marking Pins

In the standard dot peen marking mode, the electrovalve in the marking head activates the pin to precisely create individual dots. A parameter on the T7 PRO defines the dot density, measured in dots per centimeter (dots/cm). A higher dot density results in a more continuous engraved mark.

Available pin sizes include :

1) 1.5 MM

2) 2 MM

3) 3 MM

| Dimensions (H*W*L) | 90 x 390 x 280 mm |

| IP Rating | IP40 (tabletop) / IP61 (wall mounted) |

| Pocessor | Embedded quad –core Cortex –A9 , the highest frequency is 1.6 Ghz |

| Interface | RS-232, Ethernet TCP/IP, I/O, and USB; optional EtherNet/IP |

| Memory | Ram -1GB DDR3 , ROM - 8 GB EMMC solid state disk internal memory |

| Input/Output | 8 input signals , 6 output signals |

| Electric Supply | 100-240 VAC / 50-60 Hz |

| Marking Speed | Up to 10 characters per second |

| Languages | 34 available languages |

| Fonts | 5 built-in fonts, upload and use any TrueType font (TTF file) or custom font, user can also upload font as per their application |

| Text Options | Automatic serial numbering, date , month , year , hour , minute , seconds and shift codes, arc text, mirror (reverse) text |

| Logos | Upload and mark logos via USB (BMP or DXF files); built-in line, arc, and circle marking |

| 2D Codes | 2D Data Matrix and QR codes, Support Wi-Fi hotspot to connect to mobile phone , you can modify content online |

Projects Delivered

Cities

%

Satisfaction

%

Happy Customers

Benchtop & Integrated Marking Systems

Integrated Systems

Inline marking is easy with advanced controls and built-in integration capabilities.

Benchtop Systems

Inline marking is easy with advanced controls and built-in integration capabilities.

Rotary Stamping Systems

Inline marking is easy with advanced controls and built-in integration capabilities.

Different Dot Peen Marking Systems

Portable Marking Machine

Inline marking is easy with advanced controls and built-in integration capabilities.

Integrated Marking Machine

Inline marking is easy with advanced controls and built-in integration capabilities.

Table Top Marking Machine

Inline marking is easy with advanced controls and built-in integration capabilities.

Special Purpose Machine

Why to choose us?

We believe in building strong and long-term relationships with our clientele. Also, we collaborate extensively with them to understand their goals and requirements so that we can give personalised solutions that exceed their expectations.

Let’s work together !

We can’t wait to get to know you better!

Industrial Marking Sample

Find Solutions by Industry

Metal Industry

Fabrication & Construction

Automotive Industry

Maintatinance

Our Clients